| PLATINUM PLATING [PLATINIZED ANODES]

|

Platinum is one of the six metals in the "Platinum" group of noble or precious metals, all of which are excellent catalyst materials. Platinum is conductive, chemically stable and highly resistant to oxidation and corrosion. It has a silvery-gray color and can be polished to a variety of finishes.

Because of its high conductivity and low consumption rate, Platinum is an excellent anode material. Due to its high cost, Platinum is made practical for use by electroplating a thin layer over a high corrosion resistance substrate. Since Titanium, Niobium and Tantalum substrates are having the ability to form an insulating oxide film under anodic conditions, they are all most commonly used as anode in ICCP. Among them, Titanium is less expensive; however, it has a much lower breakdown potential than Niobium or Tantalum. The titanium oxide breaks down at anodic potentials in the 12 V range.

In the case of Marine application, to avoid the dissolution of titanium at unplatinized locations on the surface, the operating voltage of the anode is limited by the anodic breakdown potential of titanium, which is in the range of 9 to 9.5 V in the presence of chlorides. Hence the maximum recommended operating voltage of platinized titanium anodes is 8 V. The corresponding maximum current density output is approximately 1 kA m-2. For cathodic protection systems where operating voltages are relatively high, niobium and tantalum based anodes are generally selected. This is because these two substrates have anodic breakdown potentials greater than 100 V in chloride containing electrolytes. The wastage rate of platinized anodes is approximately 8 mg A-1 y-1.

The rate of platinum consumption has been found to accelerate in the presence of AC current ripple. Most wastage was observed to occur with AC frequencies of less than 50 Hz. The repeated oxidation/reduction processes result in the formation of a brownish layer of platinum oxide. To avoid the occurrence of this phenomenon, a single or a three phase full-wave rectification is recommended. The consumption rate of platinized anodes is also adversely affected by the presence of organic impurities such as sugar and diesel fuel.

- Pt / Ti-Nb-Ta rod anodes are widely used for internal protection of condensers, process equipment etc.

- Pt / Ti-Nb-Ta wire anodes are used for internal protection of water tanks and pipelines.

- Pt / Ti-Nb-Ta mesh anodes are used for protection of reinforced concrete structures.

|

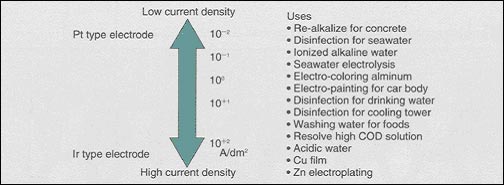

| Our Pt electrodes in other application

|

|

| General Spec. of our Platinized Anodes

|

| Substrate |

Titanium |

Niobium |

Tantalum |

| Max. Allowable operating voltage |

12V |

40V |

80V |

| Wire length |

100m |

50m |

50m |

| Wire dia |

1 / 2 / 3 / 4 mm |

| Tube length |

Max. 3000 mm |

| Tube diameter |

12 / 16 / 19 / 25 mm |

| Rod length |

Max. 3000 mm |

| Rod diameter |

6 / 8 / 10 /12 / 16 / 20 / 25 mm |

| Mesh length |

Max. 2500 mm |

| Mesh width |

Max. 800 mm |

| Pt - coating thickness |

5 / 7.5 / 10 µm |

| Consumption rate |

Approx. 8 to 16mg / A year In sea water |

|

|

|