August 2, 2022 15:01 by

admin

adminTiaano India established over 25 years with well-equipped in plant facilities and qualified engineers, delivers of MMO coated / DSA activated anode production, DSA Titanium anodes and Nickel cathodes – both Refurbishment, Recoated and Zero gap Retrofitting by using Precious metal oxides of…Iridium, Ruthenium, Palladium etc. / ENGINEERING equipment and TURNKEY projects from the single platform by using inert metals.

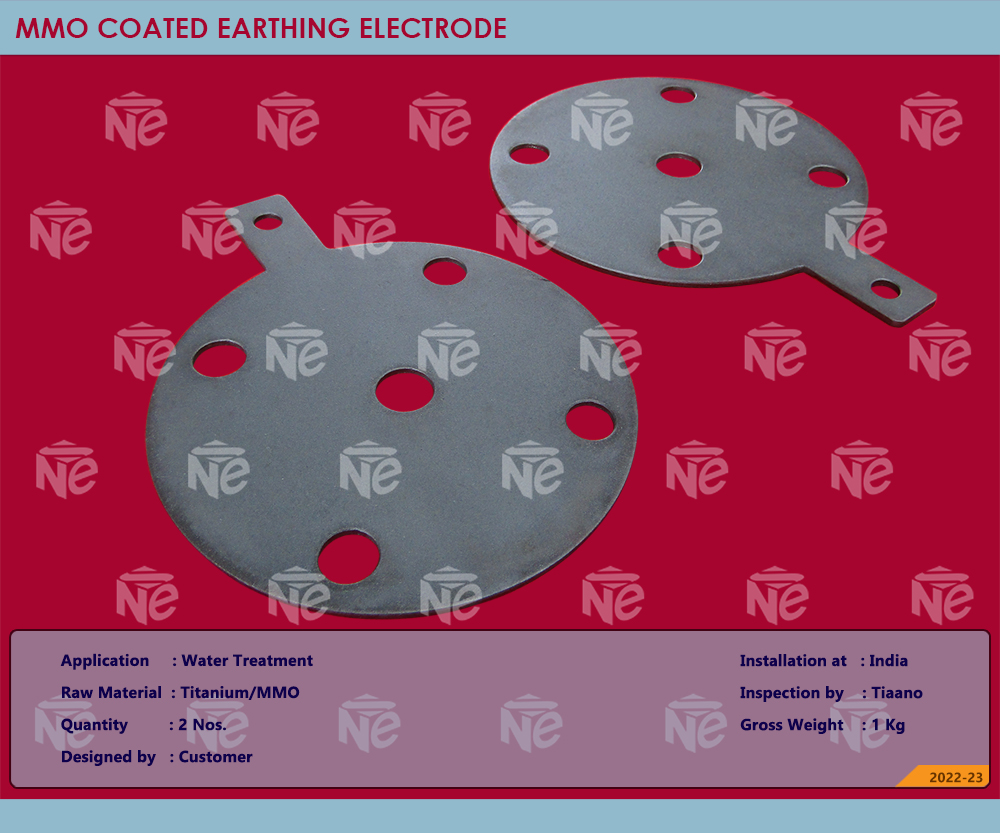

If any static potential or the stay current passed through equipment the same will be earthed by using the Earthing Electrode fitted, along with the system in the Inlet as well as outlet of Chlor Alkali System.

Finally the exit of Equipment, the water will be delivered with zero static charge of Water/any media. The specification of the Earthing Electrode depends upon the customer requirements.

Most of the Earthing Electrode substrate (Base material) is Titanium. There is a MMO (Mixed Metal Oxide) coating over the Titanium, which will be called as MMO coated Earthing Electrode and used for water treatment. These MMO Coated Earthing Electrodes have been supplied as large quantity to many of our customers.

We have in house facility to manufacture the nickel expanded mesh, which will be used for the repair and refurbishment of nickel cathodes. We design & supply inbuilt Earthing Electrodes in the inlet & outlet, there is no possibility to carry over the static charge. The detailed answer for the same is as mentioned below.

Normally any process Industry, there is a stay current or static potential available in the processed water. There is a possibility of Static Charge in the inlet due to AC power and outlet due to DC power.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com